Tubular Rivet

Tubular Rivet is a special kind of hardware accessory, also known as "hollow rivet" or "hollow nail". It is a hollow metal nail, usually made of steel, copper, stainless steel, etc., with a hollow center section.

Tubular Rivet is a special kind of hardware accessory, also known as "hollow rivet" or "hollow nail". It is a hollow metal nail, usually made of steel, copper, stainless steel, etc., with a hollow center section.

The structure of Tubular Rivet makes it very lightweight while maintaining sufficient strength, which makes it widely used in many products. These nails usually have two parts: a nail head and a nail handle. The nail head can be used to fix objects, while the hollow part of the nail handle can be used to pass through other accessories or objects to achieve fixation and connection.

The applications of Tubular Rivet in different products are very diverse, here are some common applications:

Carpentry: Tubular Rivet is commonly used in carpentry to secure boards, cabinets, furniture, etc. Since Tubular Rivet is relatively light, it can reduce the weight of the product while providing sufficient support.

Leather products: Tubular Rivet is also widely used in leather products, such as belts, shoes, handbags, etc. These nails serve as decorative elements and are also used to secure sections of leather.

Fibreboard and plastic products: Tubular Rivet is suitable for fixing fiberboard, plastic products or other lightweight materials, and can be used in the assembly of household appliances, electronic products and other products.

Outdoor sporting goods: Among outdoor sporting goods, Tubular Rivets can be used to secure tents, camping gear, etc., because they are not only lightweight, but can also pass through tent fabric and other materials, making the equipment more solid and reliable.

Leather products: In addition to leather products, Tubular Rivet is also commonly used to secure leather products, such as handicrafts, leather goods, handbags, etc.

Decoration and artwork: Some artists and handicraft makers use hollow nails as creative materials, depict them in different colors or shapes, and apply them to artworks and decorations to show unique artistic effects.

Overall, Tubular Rivet is a versatile hardware accessory whose lightness and stability make it widely used in many fields. Manufacturers and designers should choose suitable Tubular Rivets according to the needs of different products to ensure product quality and performance. At the same time, paying attention to material selection and surface treatment will help improve the durability and aesthetics of hollow nails.

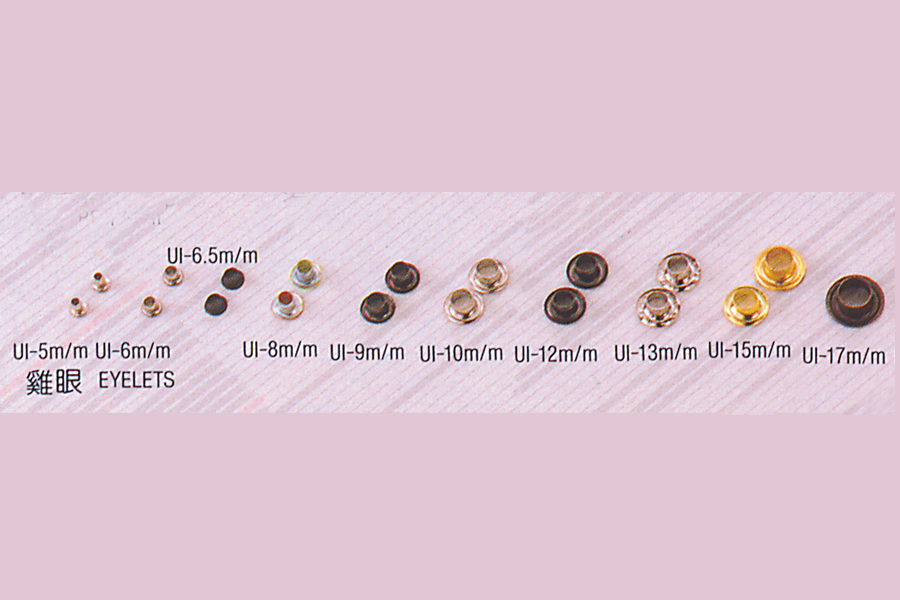

Tubular Rivet Sizes and Models: Tubular Rivet is available in a variety of sizes and models, allowing manufacturers and designers to choose the right size and model based on the needs and usage of the product. Different sizes of Tubular Rivet can be applied to products of different thicknesses and materials.

Installation method: The installation method of Tubular Rivet can be manual tapping, pressing with special tools or using mechanical equipment. Depending on the product and production process, choosing the appropriate installation method can improve production efficiency and product quality.

Surface Treatment: Tubular Rivet can be surface treated to increase its aesthetics and corrosion resistance. Common surface treatment methods include electroplating, spraying, anodizing, etc. These treatments can make hollow nails present different colors and textures.

Cross-application: Sometimes designers will combine multiple Tubular Rivets to form more complex designs, increasing the beauty and uniqueness of the product. This cross-application can be achieved by changing hollow nails of different sizes, colors and materials to create a more diverse design effect.

Durability and safety: Manufacturers should ensure the quality and durability of hollow nails to avoid breakage or loosening due to problems with the material or manufacturing process of the hollow nails. Also, the tips of cannulated nails should be blunted or rounded to reduce the risk of accidental injury.

Environmental considerations: In modern society, environmental awareness is increasing day by day, and manufacturers should focus on using environmentally friendly materials and green production processes to reduce the impact on the environment.

Overall, Tubular Rivet is an important hardware accessory that plays a key role in different product areas. Manufacturers and designers should choose suitable hollow nails based on the needs and uses of the product and ensure their quality, safety and durability. At the same time, paying attention to material selection and surface treatment, and maintaining design innovation that keeps pace with the times, will help improve the competitiveness and market position of hollow nails.

Tubular Rivet's manufacturing process: Tubular Rivet's manufacturing process includes multiple steps such as mold design, material selection, molding, machining and surface treatment. Manufacturers need to ensure that every step is strictly followed to ensure the quality and performance of hollow nails.

Hollow nails of different materials: Tubular Rivet can be made of different materials, such as steel, copper, stainless steel, aluminum, etc. Hollow nails made of different materials have different characteristics. Manufacturers and designers need to choose suitable materials based on product needs and environmental conditions.

Load-bearing capacity of Tubular Rivet: Since hollow rivets are hollow structures, their load-bearing capacity is relatively low. When designing and using products, you need to pay attention to the load-bearing limitations of hollow nails to avoid product damage or safety hazards caused by exceeding the load-bearing capacity.

Automated production: For mass-produced manufacturers, automated production is the key to improving production efficiency and quality. By introducing mechanization and automation equipment, high-efficiency production of hollow nails can be achieved.

Product testing and certification: To ensure the quality and safety of Tubular Rivet, manufacturers usually conduct product testing and certification. These tests include material testing, load-bearing testing, corrosion resistance testing, etc. to ensure that hollow nails comply with relevant standards and regulations.

International market and supply chain: As a common hardware accessory, Tubular Rivet also has extensive demand in the international market. Manufacturers need to work with global suppliers and partners to ensure stable supply and meet the needs of different regions.

In general, as an important hardware accessory, Tubular Rivet has many details worthy of attention in its application and manufacturing. Manufacturers and designers should select suitable hollow nails based on the needs and uses of the product and ensure their quality and safety. At the same time, continuous improvement of manufacturing processes and the introduction of automated production can improve production efficiency and product competitiveness.

Shockproof and shock-absorbing features: In certain applications, Tubular Rivet can be used as a shockproof and shock-absorbing device. For example, in seismic areas or places with large mechanical vibrations, proper design and use of hollow nails can increase the earthquake resistance of the product and protect the product from damage.

Repair and replacement: Tubular Rivet is removable when assembling the product, which makes repair and replacement of the product more convenient. When a product fails or a component is damaged, you only need to disassemble the hollow nail and replace the damaged part, which saves time and cost.

Decorative function: Tubular Rivet can not only be used for fixing and connecting, but can also be used as a decorative element for products. Some designers will choose hollow nails with special shapes or colors and use them on the surface of the product to add beauty and fashion to the product.

Anti-theft function: In some products, Tubular Rivet can also be used for anti-theft purposes. For example, in leather goods, Tubular Rivet can be used to fix anti-theft zippers to improve the anti-theft performance of the product.

Sound and vibration control: In some audio and mechanical equipment, Tubular Rivet can be used as a component for sound and vibration control. Its hollow structure can absorb or isolate vibration and noise, improving product performance and comfort.

No-mark fastening: Tubular Rivet secures products by passing them through objects and hiding them inside, allowing for a non-marking fastening. This is very important in the design of certain products, especially those with high aesthetic requirements.

Overall, Tubular Rivet is a versatile hardware accessory with wide and diverse applications. Manufacturers and designers should give full play to the characteristics and advantages of hollow nails according to the needs of different products to achieve the best design effects and product performance. At the same time, the material, design, manufacturing process and quality control of Tubular Rivet need to be carefully considered and improved to ensure the quality and performance of the product.