Semi-Tubular Rivet Manufacturer

A semi-tubular rivet, also known as a "center hole rivet" or "inner hole rivet," is a type of metal fastener with a hollow section in its shaft. Typically made from materials such as steel, copper, or stainless steel, semi-tubular rivets offer unique features that make them essential in various applications.

A semi-tubular rivet, also known as a "center hole rivet" or "inner hole rivet," is a type of metal fastener with a hollow section in its shaft. Typically made from materials such as steel, copper, or stainless steel, semi-tubular rivets offer unique features that make them essential in various applications.

The defining characteristic of a semi-tubular rivet is its hollow shaft, which provides specialized functionality and versatility in different industries. Compared to solid rivets, semi-tubular rivets are lighter due to their hollow structure, allowing them to penetrate materials more efficiently. This makes them ideal for securing thinner or lighter materials, such as fiberboard or cork.

Applications of Semi-Tubular Rivets

Semi-tubular rivets are used in a variety of fields due to their versatility and ease of use. Below are some of the primary applications:

Woodworking: Semi-tubular rivets are commonly employed in woodworking projects to fasten boards, cabinets, and furniture. The hollow structure allows the rivet to penetrate wood more easily, providing a firm hold.

Fiberboard and Plastic Products: These rivets are used to secure fiberboard, plastic products, or other lightweight materials. They are frequently found in household appliances and electronics, where the fasteners need to be both lightweight and durable for assembly purposes.

Leather Goods: Semi-tubular rivets also have applications in leather products such as belts, shoes, and handbags. In these cases, they serve both functional and decorative purposes, adding to the overall design of the item.

Decorative and Artistic Works: Artists and craftsmen sometimes use semi-tubular rivets in their creative projects. By painting or shaping these rivets, they can be incorporated into artwork and decorative items to create unique aesthetic effects.

Component Connection: Semi-tubular rivets can also be used to join multiple components by placing connecting materials in the hollow center of the rivet’s shaft. This allows for secure assembly of parts in mechanical devices or other equipment.

Advantages of Semi-Tubular Rivets

As a specialized hardware component, semi-tubular rivets have several advantages, particularly in specific scenarios:

Lightweight Structure: Due to their hollow core, semi-tubular rivets are lighter than solid rivets. This makes them ideal for use in applications where weight is a concern, such as with lightweight materials or when minimizing the total weight of a product is important.

Improved Penetration: The hollow design allows semi-tubular rivets to penetrate materials more easily. This makes them suitable for securing thin or delicate materials, like fiberboard and softwood, where traditional solid rivets may cause damage.

Wide Application Range: Semi-tubular rivets can be applied across different industries, from woodworking and leather crafting to electronics and appliance manufacturing. Their adaptability is one of their key strengths.

Cost-Effective: Due to their efficient design, semi-tubular rivets are generally less expensive to produce and purchase compared to more complex fastening systems. This makes them a cost-effective solution for large-scale manufacturing and assembly.

Customizable Design: The variety of materials and finishes available for semi-tubular rivets makes them highly customizable. They can be coated or finished with various surface treatments to improve both appearance and corrosion resistance.

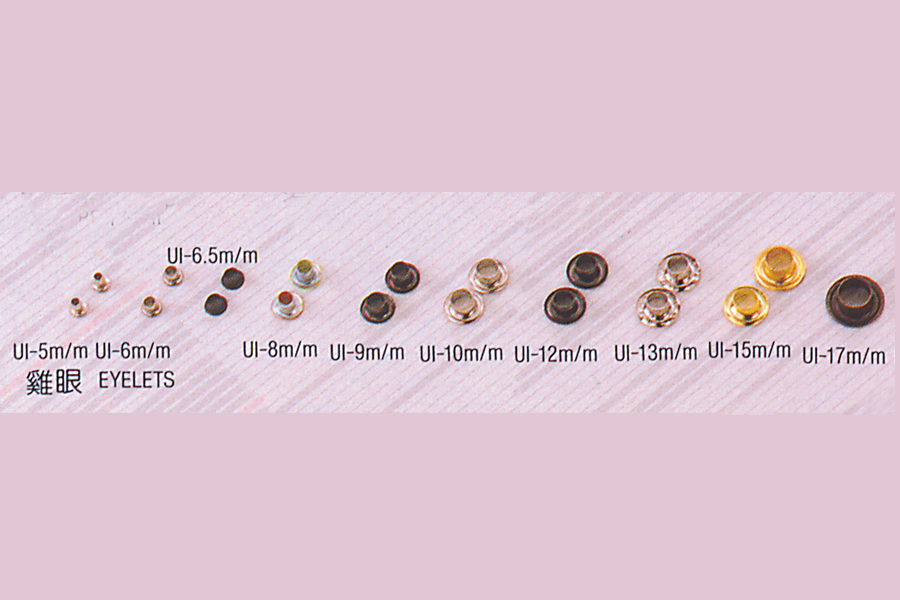

Semi-Tubular Rivet Sizes and Models

Semi-tubular rivets come in different sizes and models to accommodate various needs. Manufacturers and users should select the appropriate size based on the specific application to ensure the rivet provides adequate fastening and support. Standard sizes are typically suitable for general-purpose use, while specialized models may be required for unique or complex applications.

Safety and Reliability

The performance and reliability of semi-tubular rivets are critical for the safety of the products in which they are used. Users must ensure proper installation and choose the right size and material to avoid product failures. Incorrect installation could result in loose fittings or structural instability , potentially leading to product malfunction or failure.

Surface Treatment

To enhance the durability and aesthetic appeal of semi-tubular rivets, manufacturers often apply surface treatments such as electroplating or galvanization. These treatments help protect the rivets from oxidation and corrosion, extending their lifespan, especially in harsh environments.

Different Materials for Semi-Tubular Rivets

Semi-tubular rivets can be made from various materials, including steel, copper, and stainless steel. Each material offers different benefits, and users should select the appropriate type based on the environment in which the rivets will be used. For example, stainless steel rivets offer excellent corrosion resistance and are ideal for outdoor or marine application