Punch

The Punch: A Comprehensive Guide

A punch is a versatile hand tool used in a wide range of industries and applications, from crafting and DIY projects to professional construction, metalwork, and even jewelry making. Its primary function is to create holes or indentations in a material, guide fasteners, or mark specific points on a work surface. Punches come in a variety of types, each designed for specific tasks, ranging from fabric and leather punches for artisans to center punches and pin punches for mechanics and metalworkers.

In this detailed guide, we will explore the different types of punches, their applications, how to use them effectively, and some helpful tips for achieving optimal results in your projects.

Types of Punches

There are numerous types of punches, each suited to a particular task. Understanding the differences between them helps you choose the right tool for your specific project.

1. Hole Punch

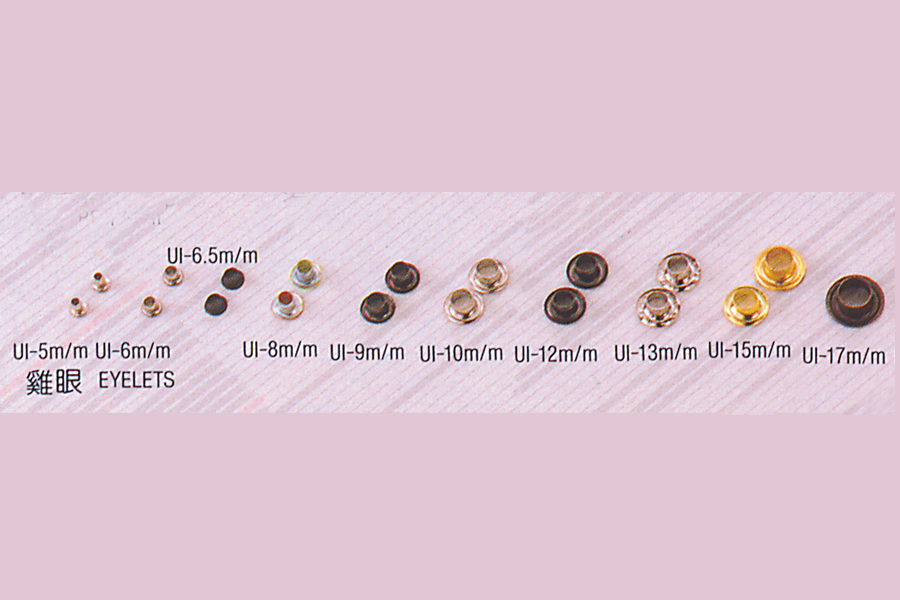

A hole punch is designed to create holes in materials such as paper, fabric, leather, plastic, and thin metals. These punches are commonly used in crafting, sewing, and stationery applications. They come in various sizes, allowing users to create precise, uniform holes. In fabric and leather work, hole punches are used to install eyelets, rivets, or grommets.

There are two primary types of hole punches:

Single-hole punches: These are typically used in DIY projects for creating a single, clean hole.

Rotary punches: These multi-hole punches come with a rotating head containing various hole sizes, making them ideal for leatherwork and other crafts where multiple hole sizes are needed.

2. Center Punch

A center punch is used to mark a specific spot on a material, usually metal, before drilling. By creating a small indentation in the surface, the center punch ensures that the drill bit does not wander or slip, allowing for precise drilling. The tool is typically struck with a hammer to create the indentation.

Center punches come in two main varieties:

Manual center punch: This requires you to strike it with a hammer to create the indentation.

Automatic center punch: This type does not require a hammer. It features a spring-loaded mechanism that creates an indentation when pressure is applied.

3. Pin Punch

A pin punch, also known as a drift punch, is designed to remove or drive out pins, bolts, or rivets from their holes. Pin punches are commonly used in mechanical, automotive, and industrial applications. The end of the punch is flat and slightly smaller in diameter than the pin it is meant to drive, allowing it to fit snugly into the hole without damaging the pin or the surrounding material.

Pin punches come in various sizes, and selecting the correct size is crucial to avoid damaging the pin or the hole.

4. Transfer Punch

Transfer punches are used to mark the center of a hole from one piece of material to another. They are particularly useful in metalworking when transferring the precise location of a hole from a template or existing part. A transfer punch ensures that the hole's location is perfectly aligned, making it easier to drill with precision.

5. Prick Punch

A prick punch is similar to a center punch but is designed for lighter, more delicate work. It creates smaller, finer indentations, making it suitable for marking soft metals, wood, or plastic. Prick punches are often used in layout work, where fine precision is required before more robust drilling or cutting occurs.

6. Cold Chisel Punch

This type of punch is used for cutting or shaping cold metal. It has a hardened steel tip that allows it to chisel away pieces of metal without heating the material. Cold chisel punches are typically struck with a hammer and are used in metalworking or construction to cut rivets, bolts, or sheet metal.

7. Leather Punch

Leather punches are specialized tools used to create holes in leather for belts, straps, and other accessories. They usually come in rotary models with multiple hole sizes or as individual hand-held punches. Leather punches are indispensable for those working with leather goods, offering clean, precise holes for rivets, eyelets, and stitching.

Applications of Punches

Punches have a wide variety of uses across different industries and applications. Below are some common uses:

1. Crafts and DIY Projects

In the crafting world, punches are often used to create holes in fabrics, leather, paper, or other materials. They are essential tools for scrapbooking, sewing, and leatherworking. Hole punches allow for the installation of eyelets, grommets, and rivets, and are often employed in the making of custom belts, wallets, handbags, and jewelry.

2. Metalworking and Machining

Metalworking professionals use punches for marking, cutting, and aligning holes. A center punch is essential for drilling accurate holes in metal, while pin punches are used for removing pins and bolts. Transfer punches, on the other hand, ensure that hole locations are perfectly aligned, making them indispensable in manufacturing processes.

3. Automotive and Mechanical Work

Mechanics often rely on punches for various tasks, such as removing or installing pins, bolts, and rivets in vehicles or machinery. Pin punches and drift punches are commonly used in the automotive industry to disassemble and reassemble components with precision. For instance, they are used to remove pins from driveshafts, suspensions, and other mechanical systems.

4. Construction and Carpentry

In the construction and woodworking industries, punches are used to mark materials before cutting, drilling, or installing fasteners. A center punch can be used to mark wood or soft metals, helping to prevent drill bits from wandering off-target. Additionally, punches may be employed to drive nails below the surface of the wood for a clean, flush finish.

5. Jewelry Making

In the field of jewelry making, punches are used to create precise holes in metals, leather, or other materials. For example, small hole punches are utilized to create holes in metal blanks for attaching chains or beads. The fine precision of a punch ensures a clean result without damaging delicate materials.

How to Use a Punch Effectively

Using a punch correctly requires careful technique and attention to detail. Here is a general step-by-step guide on how to use various punches effectively:

Step 1: Choose the Right Punch

The first step in any project involving a punch is selecting the appropriate punch for the material and task at hand. For example, use a center punch for marking a spot on metal before drilling or a hole punch to create clean holes in leather or fabric.

Step 2: Mark the Position

For punches that require accuracy, such as a center or transfer punch, begin by marking the location of the hole with a pencil, chalk, or marker. Ensuring that the punch is aligned with the marked spot is crucial for achieving precision.

Step 3: Hold the Punch Firmly

Hold the punch perpendicular to the material to ensure an even application of force. If the punch is held at an angle, it may create an uneven hole or indentation. Using a firm grip on the punch will help you maintain control during the punching process.

Step 4: Strike with a Hammer

For punches that require a hammer, such as a center punch or pin punch, use a hammer to strike the end of the punch. Begin with a light tap to ensure proper alignment, and then follow with a more forceful strike to create the hole or indentation. Be cautious with the amount of force applied—too much can damage the material, while too little may not produce a clean result.

Step 5: Inspect the Result

After using the punch, inspect the hole or indentation to ensure it is clean and precise. If necessary, you can repeat the process to deepen the hole or correct any misalignments.

Tips for Using Punches

Use a Cutting Mat: When working on softer materials like leather or fabric, place a cutting mat or scrap material underneath to protect your work surface and ensure a clean cut.

Select the Right Hammer: The type of hammer you use can impact the result. A lighter hammer is ideal for delicate work, while a heavier hammer provides the force needed for metalworking punches.

Practice on Scrap Material: Before punching your final project, practice on a scrap piece of the same material to perfect your technique and avoid mistakes.

Keep Punches Sharp: Regularly sharpen punches, especially those used on tough materials like metal. A dull punch can damage the material and produce uneven results.

Conclusion

Punches are indispensable tools across many disciplines, from crafting and metalworking to construction and automotive repair. Their ability to create holes, mark points for drilling, and align fasteners with precision makes them a critical component of any tool kit. By understanding the different types of punches and how to use them effectively, you can ensure professional-quality results in any project. Whether you're working with fabric, leather, metal, or wood, a punch offers a simple yet powerful way to enhance your craftsmanship.